The History

Leather has been used as a strong, durable and waterproof solution for tools, accessories and style for over 40,000 years. History tells of tools made for working with leather dating back to the days of the Neanderthals. The rich history of leather and tools used to fasten and optimize the material’s functionality and design have played a pivotal role in the fundamental development of our species.

From satchels to saddles, and from uses such as canvas for the world’s first pictography, to later binding the most treasured book in history, our evolution is closely synchronized with that of leather. As we grow, so too does our ability to work with the versatile material. Here, we will examine the history of leather, and how it led to the development of thermo-sensitive, heat burnishable alternatives which can now be found on many of the premier publications in the literary world today.

Leather Becomes Art

Let’s take a step back to the ancient Romans. Here, we begin to see the centralized idea of leather first being used as a luxury good. Seen as both a form of currency, as well as for fashion, leather was quickly beginning to represent the wealth and status of upper class citizens.

On top of that, we begin to see the idea that communication was an ever expanding necessity during this time. Here, we begin to truly realize the importance of recording our thoughts and history in text. Examples of published works being transcribed both on, and bound within leather coverings begin to grow more prominent… But the skill behind working with leather was quickly becoming a well kept secret. Leather work became a closely guarded trade kept by the top Guildsman in the industry at the time.

Our use of leather was transitioning from that of necessity to that of an art-form.

In the 16th century, Spain had taken over as the world leaders in leather craftsmanship. Developing new ways of utilizing, embellishing and customizing leather, they brought these newfound skills to the Americas. Here, we see the basic geometric pattern embellishments begin to transition into beautiful and extravagant floral designs. What we now consider to be modern leather artistry has been created.

Faux Leather Options Arise

Though its price remains in the higher spectrum of materials in the cover material industry, the artisanship of the craft can still be found in high end, luxury finished products. As a result, there has been an increase in less expensive faux leather cover solutions that provide the look and feel of the real thing, plus additional design qualities that real leather simply cannot withstand.

Here, we begin to see materials which represent the same look and feel of leather, but which allow for more intense and consistent heat burnishing capabilities. That, matched with a diverse range of color capabilities being available at a more cost effective price has driven leather alternatives to become the easy modern day solution for designs that call for the rugged richness of leather with the ease and cost effectiveness of a more modern solution.

What is Heat Burnishing

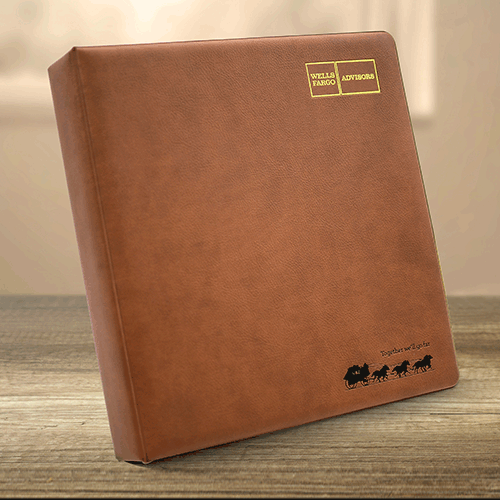

The act of heat burnishing is simple. It is the hot stamping of a pattern or design into the material which leaves a fine, crisp, darker notation of the die. Book covers that utilize heat burnishing have become a staple in the publishing world, especially in the religious market. The incorporation of a crisp, intricate design conveys an immediate sense of quality and luxury to a finished product, and helps establish a design in more ways than one.

The options and intricacies of burnishing a quality piece of PU and faux leather is seemingly endless. The stamped patterns, titles, words and foils directly into the cover are designs that you can touch, feel and admire all at once.

Thermosensitivity

Of course, only materials which are designed for heat sensitivity are capable of receiving heat burnishing. This is one of the main advantages of using quality faux materials over leather as it consistently maintains better thermosensitivity.

Alpha

Ecological Fibers is proud to be able to provide one of the most consistent and dependable PU cover materials in the industry with Alpha PU.

A top-of-the-line synthetic leather cover material, Alpha products are a thermo-sensitive, non-woven cover material which offer the genuine matte, soft-touch finish, replicating the supple feel of leather. Available in a number of different colors and embossing patterns, Alpha has risen to the top of the faux-leather industry.

Alpha products also offer an excellent surface for stamping and burnishing, with optimal sustainability — CPSIA and REACH 161 complaint, solvent and heavy metal-free, and passing all SGS requests — Alpha materials bring a sophisticated level of design to the luxury stationery, packaging, and book markets.

Alpha Aston®

Heat Burnishing: Temp: 320-356°F / 160-180°C

Foil Stamp: Temp: 230-348°F / 110-120°C

Alpha Cowhide®

Heat Burnishing: Temp: 320-356°F / 160-180°C

Foil Stamp: Temp: 230-348°F / 110-120°C

Alpha Goat®

Heat Burnishing: Temp: 320-356°F / 160-180°C

Foil Stamp: Temp: 230-348°F / 110-120°C

Alpha Skiver®

Heat Burnishing: Temp: 320-356°F / 160-180°C

Foil Stamp: Temp: 230-348°F / 110-120°C

The Alpha products listed above are those that are kept in stock here in our Rhode Island and Massachusetts facilities. Please contact your designated sales rep for further inquiry about non-stock Alpha items that also may be available.

Mirage®

Mirage® is our in-house solution to sustainable faux-leather cover materials. This paper-based, thermo sensitive product is available in a number of different color and embossing options, providing a diverse range of selections to choose from.

This eco-friendly acrylic coated material offers the same style and heat-burnishing qualities as a PU product, providing a clean slate for your own creative designs. From our flush antique Mirage® Classic, to the vivid, heat activated embossing patterns found in our Corsica, Nouveau, Distressed lines, and more, Mirage® provides state of the art look, feel, and heat burnishing effects.

All colors are created to comply with our strict ecologically sound production methods, ensuring that they remain FSC® certified (RA-COC-003258) and EU REACH, TSCA, RoHS, CPSIA, ISQ 8124 PART 3, ASTM F963, Prop. 65, EN 71 compliant.

Mirage® Classic

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® Corsica

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® Distressed

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® Nouveau

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® Pescara

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® Vintage

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

Mirage® 325gsm

Heat Burnishing: Temp: 275 to 300°F / 135-149°C

Pressure: 60 to 80 PSI

Dwell Time: .5 to 1 second

For branding it is recommended to use TEFLON coated stamping die to achieve best results.

The Future is Bright

Ecological Fibers is always on the lookout for the next big improvement in the sustainable cover material market, and we will continue to strive towards developing the future successes of the industry. New and exciting things are on the horizon, with significant developments underway for the future of thermosensitive materials.

To stay up to date with any future developments, be sure to sign up for our newsletter and follow us on social media as we continue to produce and create the highest quality and most environmentally sound cover solutions in the world. For more information on any of our leather or thermo sensitive materials, please contact your designated sales representative today.